“Cloud Nine”-hot humbucker

The “Cloud Nine”-hot humbucker is a versatile ROCK pickup with plenty of mids, plenty of power but with enough clarity to help you stand out in the mix.

I am at heart a man of ROCK.

Since the advent of the DiMarzio Super Distortion players have been able to get some power out of their pickups, enough to really push an amp.

The neck pickup needed to be clear and present but with enough power for some of those sweet lead lines. I wanted the bridge pickup to have power to scream with the best of them while retaining enough clarity to have definition. When I play a 7th chord I want to hear it as a 7th and not sound mushy like a John Deere tractor at full throttle. It’s a real danger with hot pickups that they lose character and tone. I needed a crunchy rhythm with strong mids and an over the top lead sound. I want to get squawking pinched harmonics whenever I please. Not only that but I need it it to clean up nicely and react well to a treble bleed circuit. A humbucker for every situation, for players not afraid of a bit of gain.

Not much to ask, eh!

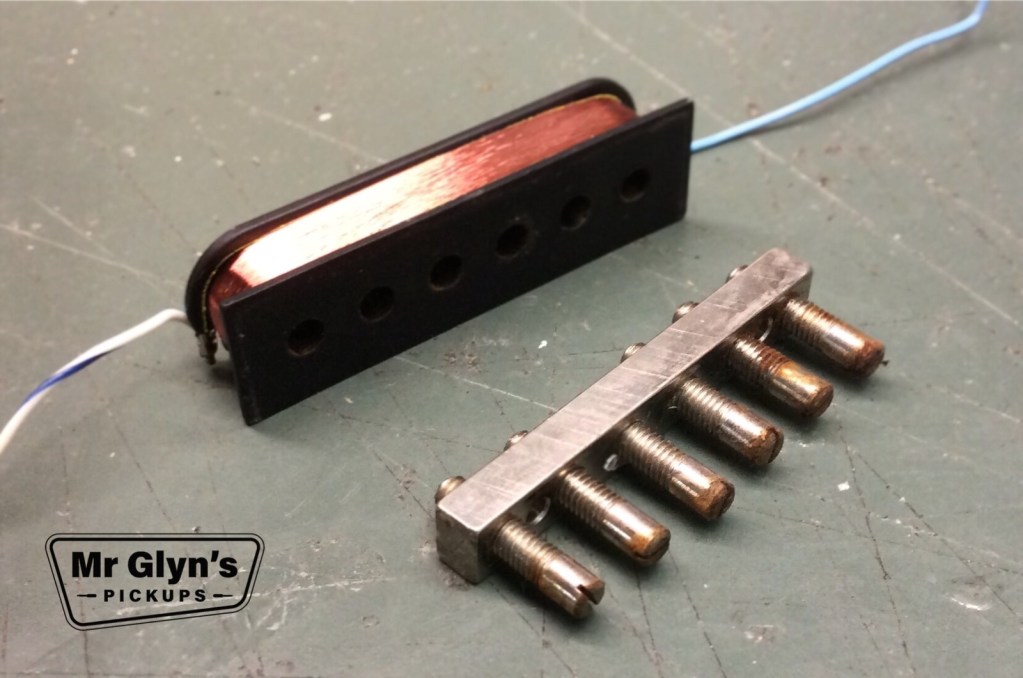

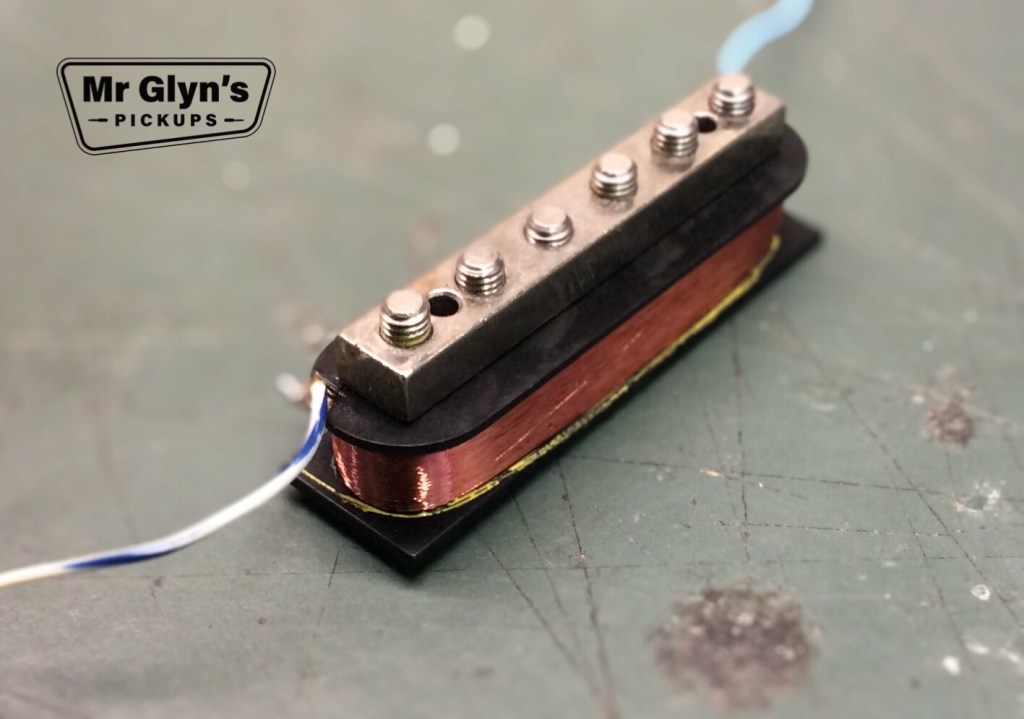

I got through a lot of wire and magnets experimenting over the years to get this set right. I suppose I worked on it for about 5 years, different magnets, winds, wire thickness, insulation, winds per layer – there are a lot of factors. Whenever I felt I was close I used them at a gig to hear how they sat in the band. Pickups can sound quite different next to a drummer or in a mix. I tweaked and adjusted…

Eventually I was happy with the design and I was lucky enough to have legendary Kiwi band ‘Head Like A Hole’ help out with road testing. I knew if they came back from tour happy then I was on to a winner. They did.

When you get it right it feels so good, a sensitive pickup rich in harmonics is so much fun so I called it the “Cloud Nine” which how I felt at the end of it all.

This is the pickup set I gig with myself in my covers band now. I have them in an Epiphone Sheraton with treble bleeds on the volume pots. With this set up it works for everything from The Smiths to Metallica and all points in between. I don’t feel the need to swap guitar – these pickups work for everything.

Here are some sound samples recorded clean through a Fender Princeton Reverb-Amp. The overdrive sounds are using an Electroharmonix Soul Food. The guitar is a ’98 Les Paul Std with D’Addario 10-52’s. All of them with the same guitar, same amp, same settings, no reverb or eq added later.