I’ve been repairing a few pickups recently and I thought I’d share this one with you. It’s a Fender Lead I Pickup that was sent to me by guitar repairer Jeff Baker from Oamaru.

The Fender Lead I was one of those obscure models that never really caught on and the pickup reflects that. It’s a little unusual and that’s what makes it interesting.

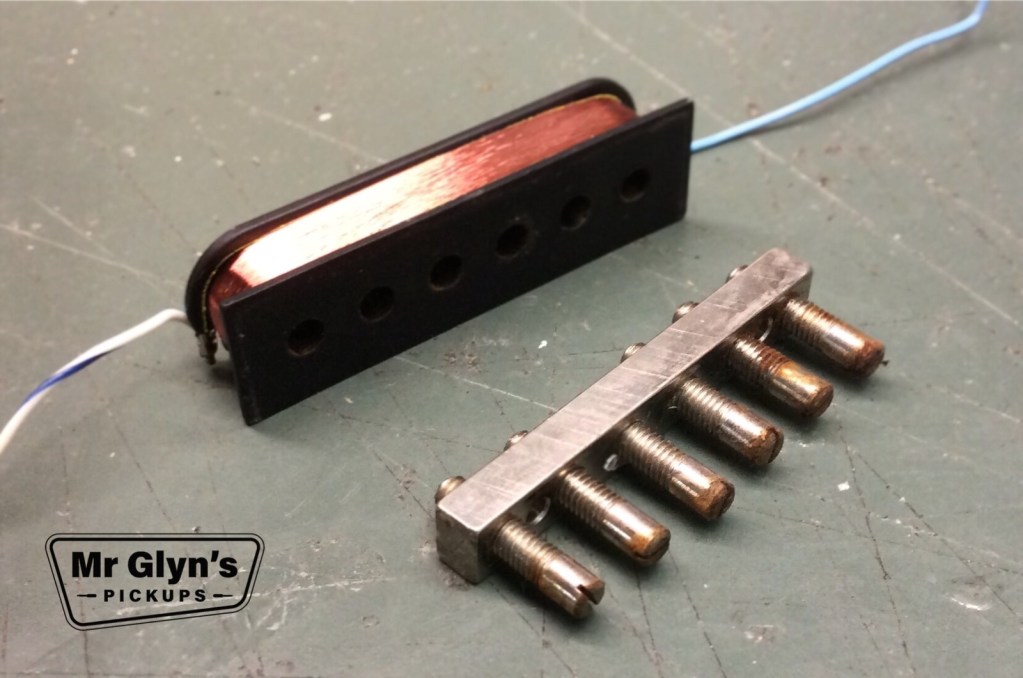

It even looks different with those square topped bobbins.

Not only is it unusual looking from the top but turn it over and it shows what it’s really all about. Those are 12 big adjustable poles screwed into substantial steel blocks and coupled to a powerful ceramic magnet.

This is clearly not a typical Fender pickup, this was designed to ROCK.

It came to me because it wasn’t working and typically one coil was showing ‘open circuit’ on the test meter. In these cases I can use the good coil as a reference to what the faulty coil should be. It had a dc resistance of 7.61 KOhms. Wiki told me the final dc resistance of the whole pickup is approx. 13KOhms so that gave me a pretty good indication of how I should wind it. That’s a powerful set of coils to go with that magnet.

A bit of maths, plenty of experience and some intuition and I had a plan for winding it. Detailed information just isn’t available for this kind of job.

I stripped the bobbin and wound the coil.

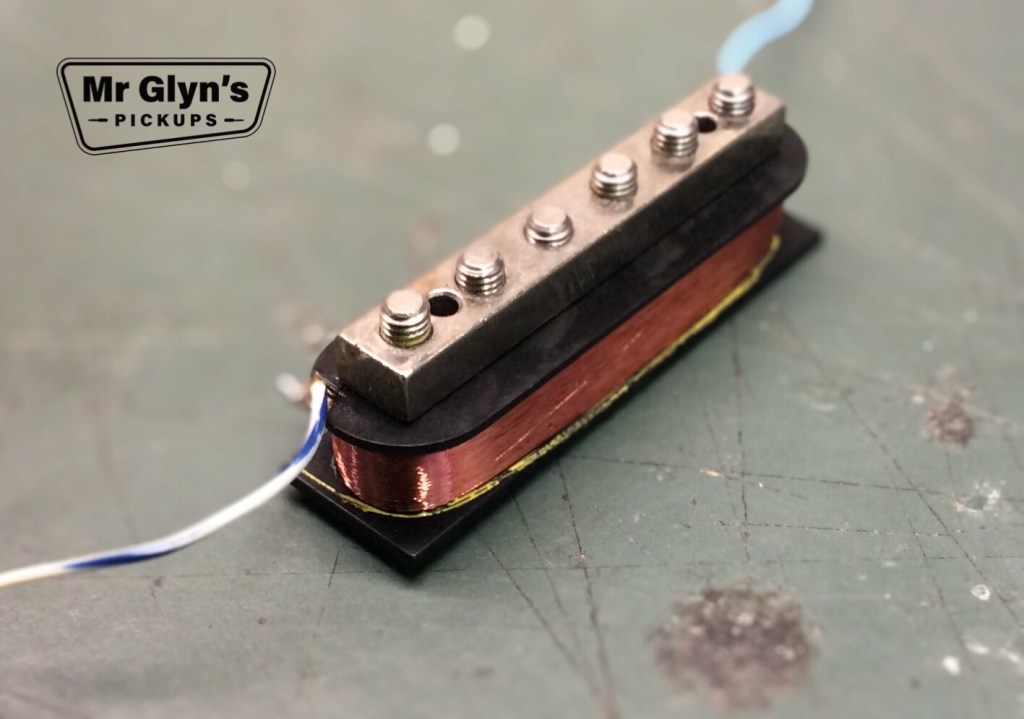

I potted it very lightly because these bobbins are made of butyrate that has a lower melting point than most modern ABS bobbins – I didn’t want it to deform with the heat, I wasn’t going to be able to get another bobbin.

Here you can see the chunky pole pieces, they’ll guide a fair bit of that ceramic magnet’s strength up to the strings.

If you have a faulty pickup or are interested in my range of handmade pickups have a look at the website

https://www.youtube.com/c/MrGlynsPickups/videos