A customer brought me a 'dead' Strat style pickup the other day. It's out of an 80's Yamaha but its identical to a Fender in design.

I see quite a few old Fender pickups that have suddenly started to sound thin and quiet. It's a common problem, the insulation breaks down over time shorting out the pickup.

The fate of this pickup was sealed when it's owner decided to adjust the pole piece height. It has the vintage style staggered poles, they are not adjustable, if you push them in it will sheer of a load of wires and kill the pickup.

I like pickups, I like rewinding them. It's such simple high school physics but so fundamental to electric guitars.

A pickup is simply a magnet with a coil of very thin wire wrapped around it. If you pass something ferrous through the magnetic field (a vibrating string) it disturbs the field causing electrons in the coil to move - that' electricity. It's not much electricity but amplify it a couple of times and you've got stadium ROCK. Cool eh.

To make a pickup sound good is rather more complicated, in fact, rather surprisingly so considering the basic principle is straight forward.

I tested the pickup and the meter showed it was dead. Before snipping all the windings off I just re-solder the wire terminals just in case of dry joints, this does sometimes fix it , worth a go.

In order to re-wind it I need to cut off the old windings. The wire is as fine as hair (I'm judging by my own) and there are thousands of turns of it. I'm careful not to damage the bobbin while doing this. Any little nicks can catch on the new windings and ruin an otherwise good rewind.

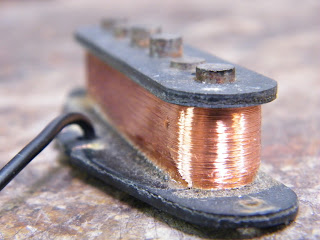

The old windings are off now and you can see what happened.

The two highest pole pieces that were pushed down have torn the protective tape and sneered off some of the turns.

You can see what a simple structure a Fender pickup is. Each of the 6 lugs is an alnico magnet press fitted into vulcanised fibre board. I use a blade to scrape off any excess wax and smooth out any high points.

I seep very thin superglue into the magnet/fibreboard joints just to be sure it's all still strong.

I replace the tape with some thinner stuff. The tape increases the life of a pickup by preventing the inner windings from shorting out on the pole piece. I use really thin tape to keep the inner windings as close as possible to the magnet. There's a lot of high end clarity that comes from these inner windings. This pickup is ready for the winding machine.

I mount the pickup to the machine with an extra little block to keep the underside straight. Some vintage pickups can get a bit bendy without this support when winding.

I anchor the wire by wrapping it through the lug 4 or 5 times.

I prefer to wind with a combination of scatter winding by hand and machine winding. I've tried so many different ways over the last 20 years, this works best for me.

Here's the finished coil. You can see it looks slightly uneven, that's intentional. If you wind a pickup too neatly it sounds a bit dull. An element of randomness creates a loose, open clarity.

I've wound this one with 8500 turns of 42AWG wire. It's come out at 6.2 KOhms which was about what I wanted. This is a bridge pickup and the other two are 5.6KOhms wound with the same gauge wire. So it should match in well.

And we're done - this Strat pickup lives to ROCK another day

Feel free to contact me, mrglynspickps@gmail.com

No comments:

Post a Comment

Note: only a member of this blog may post a comment.